MANUFACTURING

To Drive Industry 4.0

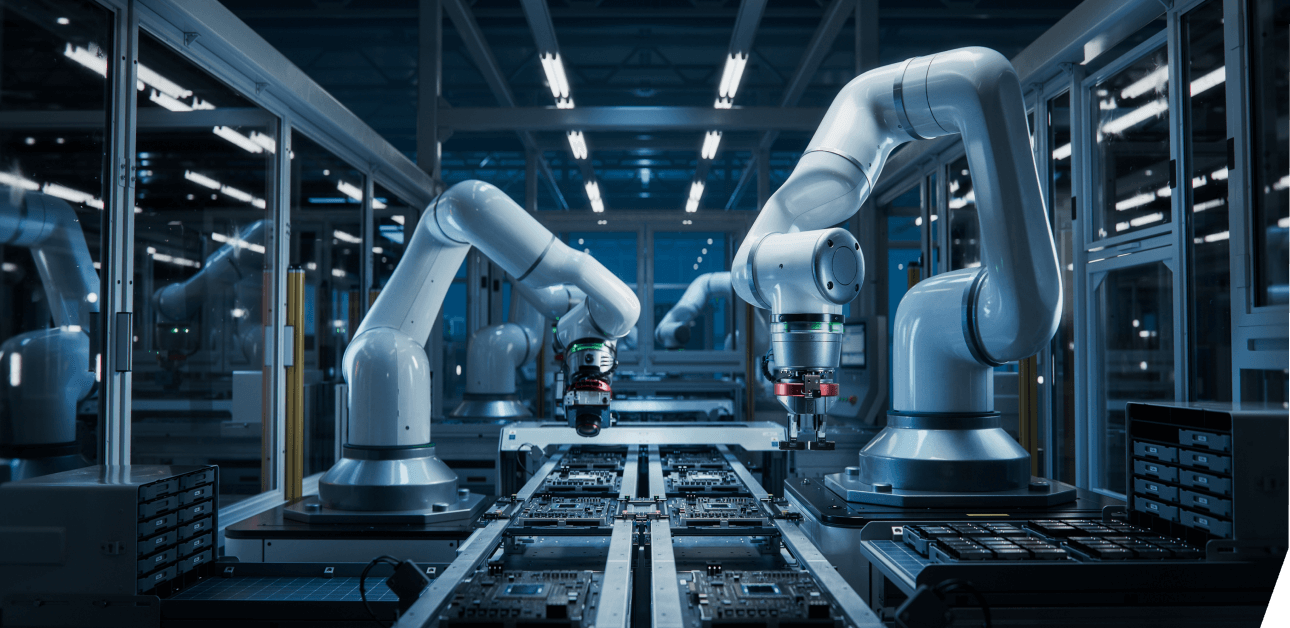

Manufacturers face high CAPEX pressures, production inefficiencies, and supply chain disruptions. To combat evolving challenges, WAISL offers cutting-edge digital transformation tools like digital twin and AI/ML solutions, integrated command centers, and video analytics. Fortified by robust technology infrastructure, master system integration, and business intelligence, our scalable solutions transform production lines into dynamic, connected ecosystems.

Let tech handle the heavy lifting.

Optimising Production in a Digital Era

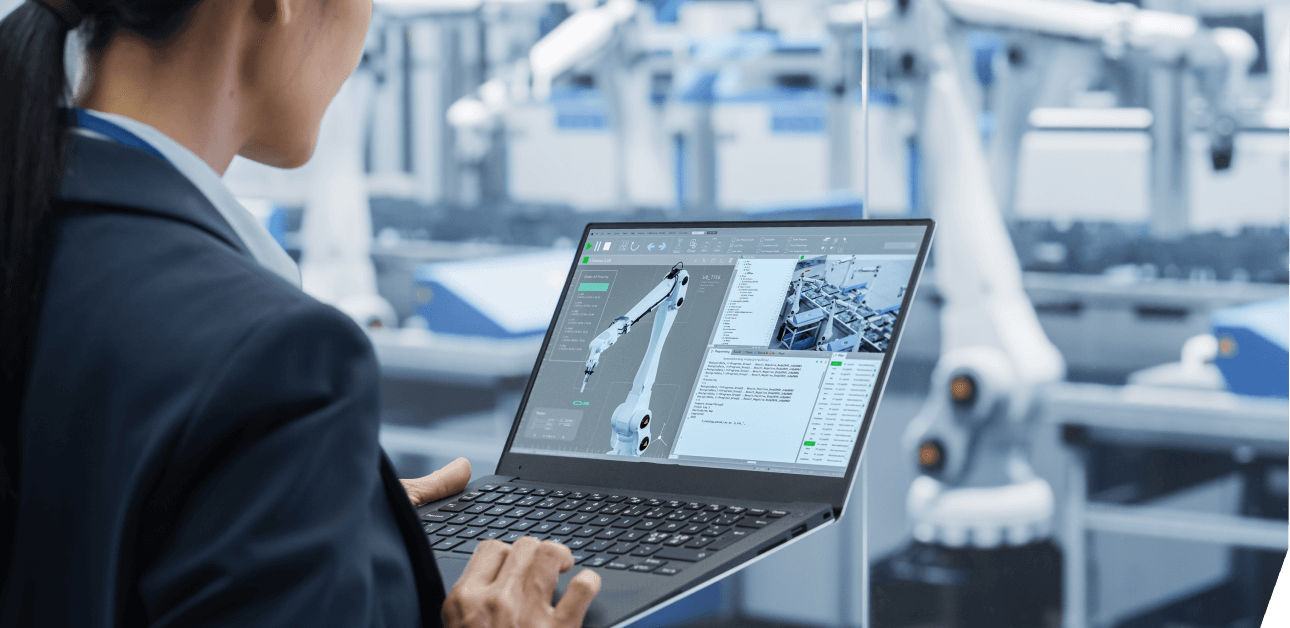

WAISL’s proactive, future-ready approach leverages use cases like digital twin and robotics integration and integrated command centres, enabling predictive maintenance, agile resource allocation, and streamlined scheduling to minimising downtime and boost throughput.

Industrial Renaissance: Championing the Future of Smart Manufacturing

WAISL stands at the forefront of Industry 4.0, pioneering innovations that drive operational excellence. Our thought leadership is rooted in our ability to integrate advanced digital tools with traditional manufacturing processes, setting new industry standards for efficiency, safety, and innovation.